Pasiuna nga Organa

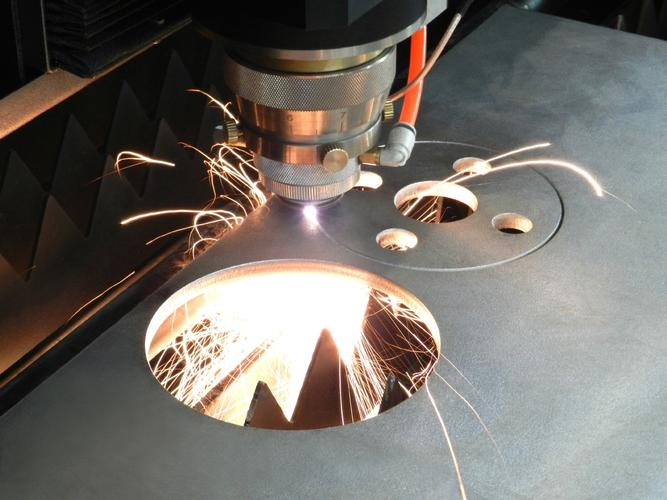

Ubos sa estratehikong paglansad sa "Gihimo sa China 2025," Ang tradisyonal nga industriya sa industriya sa China nag-antus sa usa ka lawom nga pagbag-o nga gimaneho sa automation, intelligence, informatization, ug network. Uban sa labing maayo nga pagpahiangay sa automation ug digitalization, ang teknolohiya sa pagproseso sa laser nagkadaghan sa mga industriya sama sa automotive, aerospuilding, aerospuilding, steel, medical device, ug 3C electronics. Lakip niini, ang panginahanglan alang sa mga kagamitan sa pagputol sa laser padayon nga nagtubo. Ingon nga ang mga kagamitan sa laser naglihok padulong sa mga aplikasyon nga high-end, nga gipadagan sa mga kinahanglanon sa 3C nga mga kinahanglanon sa pagkontrol sa laser - nailhan nga mga "utok" nga labi ka higpit.

Sa aktuwal nga proseso sa produksiyon sa pagproseso sa laser, "taas nga katukma, taas nga kaepektibo, ug tulin nga tulin" mao ang sukaranan nga mga panginahanglanon sa mga kagamitan sa pagputol sa laser. Kini nga mga gipangayo suod nga may kalabutan sa pasundayag ug mga algorithm sa sistema sa pagkontrol. Ang sistema sa pagpugong nag-impluwensya sa impeksyon sa produksiyon sa produksiyon ug kalidad sa workpiece. Ingon nga ang core controller sa sistema sa pagputol sa laser, ang Industrial PC (IPC) mao ang responsable sa pagdawat ug pagproseso sa mga panudlo gikan sa mga panudlo sa CNC nga kini nga mga panudlo sa piho nga mga aksyon. Pinaagi sa tukma nga pagkontrol sa mga parameter sama sa posisyon, katulin, ug gahum sa laser beam, gisiguro sa IPC ang episyente ug tukma nga pagputol sa mga piho nga gipamutol nga mga agianan ug mga parameter.

Ang usa ka nanguna nga kompanya sa domestic nga espesyalista sa mga sistema sa pagkontrol sa motion nagpalihok sa mga tuig sa R & D, ang pag-eksperimento sa kapakyasan sa pagputol sa laser nga adunay kaarang nga pagputol sa laser nga pag-ayo sa pagputol sa laser nga pag-ayo sa pagputol sa pag-cutter sa natad ug kalidad sa pagproseso sa mga kustomer niini. Kini nga solusyon espesipikong na-optimize alang sa mga sistema sa pagputol sa BEVRVEL sa industriya sama sa paghimo sa istruktura sa steel, ug mabug-at nga makinarya alang sa katukma ug pagkaayo.

Ang Cally-Contad Industrial Computer IPC330D usa ka high-performance industrial PC nga piho nga gidisenyo alang sa lainlaing mga sitwasyon sa industriya. Nga nagpakita sa usa ka disenyo sa hulaw sa aluminyo nga nagsiguro nga malig-on ug kasaligan nga pasundayag samtang nagtanyag sa labing maayo nga pagkabungkag sa kainit ug kusog nga istruktura. Kini nga mga bentaha naghimo niini nga kaylap nga gisagop sa mga sistema sa pagkontrol sa laser, nga naghatag lig-on ug kasaligan nga suporta sa pasundayag. Sa kini nga kaso, gigamit sa kliyente ang IPC330D-H81L2 ingon nga yunit sa pagkontrol sa core, nga nakab-ot ang mosunud nga mga sangputanan sa pag-optimize:

- Gipalambo nga kalig-on, epektibo nga pagkunhod sa mga isyu sa pag-vibrate sa panahon sa proseso sa pagputol.

- Kompensasyon sa Error, hinungdanon nga pagpalambo sa pagputol sa katukma.

- Gisuspenso nga pagputol, nga nagtugot sa episyente nga paggamit sa materyal ug pagtipig sa gasto pinaagi sa pagsuporta sa gisuspinde nga pagputol sa sulab.

Mga dagway sa pasundayag sa APQ IPC330D:

- Suporta sa Proseso: Kumpleto sa Intel® 4th / 6 hangtod ika-9 nga Gen Core / Pentium / Celeron Desktop CPU.

- Gahum sa Pagproseso sa Data: May katakus sa pagdumala sa lainlaing mga sulud sa sulud nga kompyuter nga hapsay.

- Flexible Configurasyon: Gisuportahan ang sumbanan nga ITX nga mga motherboard ug 1U nga mga suplay sa kuryente nga adunay mga opsyonal nga adapter cards alang sa duha nga PCI o usa ka PCIE X16 nga pagpalapad.

- Desinyo nga Promedy sa Gumagamit: Ang laraw sa switch sa panel nga adunay mga indikasyon sa gahum ug storage.

- Daghang Pag-instalar: Nagsuporta sa daghang direksyon nga dingding nga na-bait o pag-instalar sa desktop.

Mga Kaayohan sa IPC330D sa mga sistema sa pagputol sa laser nga nagpunting:

- Pagpanambal sa motion: Ang 4-axis motion control nakapahimo sa taas nga koordinado nga mga lihok alang sa tukma ug high-speed laser cutting.

- Koleksyon sa Data: Nakuha ang lainlaing datos sa sensor sa panahon sa proseso sa pagputol, lakip ang gahum sa laser, pagputol sa tulin, focal gitas-on, ug pagputol sa posisyon sa ulo.

- Pagproseso sa Data ug Pag-adjust: Mga proseso ug pag-analisar sa datos sa real-time, nga nagtugot sa dinamikong pag-adjust sa mga parameter sa pagputol aron masiguro ang kalidad sa ECICICT ERROR ERROR COMPRACTION.

- Mga Mekanismo sa Pag-opera sa Kaugalingon: Gisangkapan sa proprietary sa APQ nga tagtabang sa IPC ug IPC Manager Software alang sa hilit nga kontrol ug pagdumala, pagrekord sa sayup, pagrekord sa datos aron suportahan ang pag-record sa sistema ug pag-opera.

Nahibal-an nga ang limitado nga wanang sa pag-install usa ka kasagaran nga hagit sa mga setting sa industriya alang sa mga kagamitan sa pagputol sa laser, gisugyot sa APQ ang usa ka gi-upgrade nga solusyon sa pagpuli. Ang compact nga magazine-estilo nga intelihente nga tigpugong sa AK5 gipulihan ang tradisyonal nga mga industriya sa industriya sa dingding nga gipahimutang. Gipares sa PCIE alang sa pagpalapad, gisuportahan sa AK5 ang HDMI, DP, ug VGA Triple Display Awtoms, Duha o Walo Opticallated Digital output. Nagpakita usab kini usa ka gitukod nga USB 2.0 nga tipo-usa ka pantalan alang sa dali nga pag-instalar sa mga dalag sa seguridad.

Mga Kauswagan sa Solusyon sa Ak5:

- Proseso sa High-performance: Gipangunahan sa N97 processor, gisiguro niini ang lig-on nga pagproseso sa datos ug pag-compute sa taas nga tulin, nga nagtagbo sa mga gipangayo sa komplikado nga intelihente nga software software.

- Compact laraw: Gagmay, ang pagdesinyo nga dili mahimo nga pag-instalar sa wanang sa pag-install, gipamubu ang kasaba, ug gipalambo ang kinatibuk-ang kasaligan.

- Pagpahiangay sa Kalikopan: Resistensya sa grabe nga temperatura, makaarang sa lig-on nga operasyon sa mapintas nga mga palibot sa industriya.

- Data Security: Gisangkapan sa mga supercapacitor ug proteksyon sa gahum sa pag-drive aron mapanalipdan ang kritikal nga datos sa kalit nga mga outage sa kuryente.

- Kusog nga Kapabilidad sa Komunikasyon: Gisuportahan ang Ethercat Bus alang sa high-speed, pag-synchronize sa transmission transmission nga datos, pagsiguro sa tinuud nga komunikasyon tali sa gawas nga mga aparato.

- Diagnosis sa Sayup ug Pasidaan: Gi-apil sa IPC Assistant ug IPC Manager alang sa pag-monitor sa real-time nga pag-monitor sa kahimtang sa operasyon, pag-ila ug pagtubag sa mga potensyal nga isyu sama sa pag-disconne.

Samtang nagpadayon ang paghimo sa pag-uswag ug pag-uswag sa mga teknolohiya, ang mga high-flexibility nga mga sistema sa pagputol sa pagputol sa laser nagkadaghan nga nagpalihok sa salabutan, pagkaayo, ug katukma. Pinaagi sa pag-apil sa artipisyal nga paniktik ug mga teknolohiya sa pagkat-on sa makina, kini nga mga sistema mahimo nga labi ka maalamon nga mahibal-an ug madumala ang lainlaing mga sitwasyon sa pagputol ug pagkaayo. Dugang pa, uban ang pagtungha sa mga bag-ong materyales ug proseso, ang mga high-flexible nga pagputol sa mga sistema sa pagputol sa laser kinahanglan nga padayon nga mag-update ug mag-upgrade aron matuman ang mga bag-ong kinahanglanon sa pagputol ug mga hagit sa teknolohiya.

Ang APQ nagpabilin nga komitido sa paghatag og malig-on ug kasaligan nga mga PCS sa Indical alang sa mga sistema sa pagputol sa laser, pagsiguro sa pagkolekta sa datos ug pag-apil, pag-apil sa interface sa gumagamit, ug kalig-on. Pinaagi sa pagsuporta sa dugay nga lig-on nga operasyon sa mga sistema sa pagputol sa laser, ang APQ makatabang sa pagpalambo sa kahusayan sa produksiyon ug kalidad sa produkto, pag-drive nga labi ka maalam nga pag-uswag sa industriya.

Kung interesado ka sa among kompanya ug mga produkto, mobati nga gawasnon sa pagkontak sa among representante sa Overseas, Robin.

Email: yang.chen@apuqi.com

WhatsApp: +86 18351628738

Post Oras: Dis-20-2024