पृष्ठभूमि परिचय

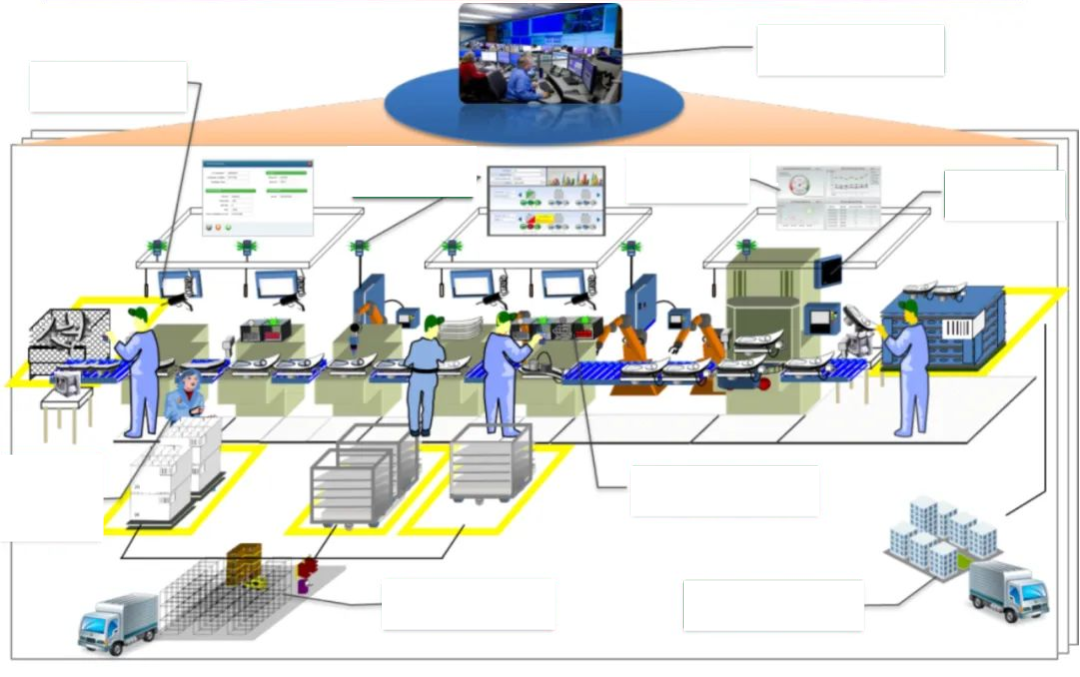

प्रौद्योगिकी के तेजी से विकास और नए उत्पादन बलों के प्रस्ताव के साथ, डिजिटल परिवर्तन एक अपरिहार्य प्रवृत्ति बन गया है। डिजिटल प्रौद्योगिकियां पारंपरिक स्टॉक व्यवसाय का अनुकूलन कर सकती हैं, उत्पादन और लेनदेन के स्तर में सुधार कर सकती हैं, और दक्षता में सुधार, लागत में कमी और गुणवत्ता वृद्धि प्राप्त कर सकती हैं। उदाहरण के लिए, विनिर्माण उद्योग इंटरनेट ऑफ थिंग्स (IoT), बिग डेटा और आर्टिफिशियल इंटेलिजेंस (AI) जैसी प्रौद्योगिकियों को पेश करके स्वचालन और बुद्धिमान उत्पादन प्रक्रियाओं को प्राप्त कर सकता है, जिससे उत्पादन दक्षता में काफी सुधार हो सकता है। डेटा से पता चलता है कि कुछ पारंपरिक उद्योगों ने पायलट इंटेलिजेंट मैन्युफैक्चरिंग प्रोजेक्ट्स को लागू करने के माध्यम से, उत्पादन दक्षता में 37.6%की औसत वृद्धि देखी है, ऊर्जा उपयोग में 16.1%की वृद्धि हुई है, और परिचालन लागत में 21.2%की कमी होती है।

पारंपरिक विनिर्माण उद्यम डिजिटल परिवर्तन प्रक्रिया के दौरान प्रौद्योगिकी, अनुभूति और रणनीति में विभिन्न चुनौतियों का सामना करते हैं। तकनीकी चुनौतियों में उपकरण उन्नयन, सिस्टम एकीकरण और डेटा सुरक्षा शामिल हैं। उद्यमों को लक्ष्यों और रणनीतिक योजनाओं को परिभाषित करना चाहिए और स्वचालन, खुफिया और डिजिटल प्रबंधन को जल्दी और प्रभावी ढंग से प्राप्त करने, दक्षता बढ़ाने, लागत को कम करने, उत्पाद की गुणवत्ता में सुधार करने और प्रभावी व्यावसायिक मॉडल और प्रतिस्पर्धी लाभ बनाने के लिए उपयुक्त निर्माण समाधान चुनने चाहिए।

इसलिए, अधिकांश पारंपरिक उद्यमों के लिए, डिजिटल परिवर्तन के कार्यान्वयन को निम्नलिखित दिशाओं पर विचार करने की आवश्यकता है:

- पहले डेटा संग्रह

डेटा संग्रह डिजिटलाइजेशन की नींव है। डेटा के साथ, उत्पादन प्रक्रियाओं की निगरानी की जा सकती है, संसाधनों को अनुकूलित किया जा सकता है, और दक्षता और उत्पाद की गुणवत्ता में सुधार किया जा सकता है। - नियंत्रण लागत

डिजिटल परिवर्तन के लिए दीर्घकालिक निवेश की आवश्यकता होती है। एक "छोटा, तेज, हल्का, सटीक" उत्पाद समाधान छोटे और मध्यम आकार के उद्यमों पर वित्तीय दबाव को कम कर सकता है। - प्रतिरोध को कम करें

परिवर्तन प्रतिरोध को कम करने और तेजी से तैनाती प्राप्त करने के लिए मौजूदा प्रबंधन मॉडल के साथ संगत समाधान का चयन करें। - उत्पादन लाइनों पर ध्यान केंद्रित करें

डिजिटलाइजेशन के शुरुआती चरणों में, व्यापार और उत्पादन स्थिरता सुनिश्चित करने के लिए उत्पादन उपकरणों को अपग्रेड करने और प्रक्रियाओं को अनुकूलित करने पर ध्यान केंद्रित करें। - छोटे से शुरू करें, धीरे -धीरे विस्तार करें

परिणाम प्राप्त करने के लिए सरल परियोजनाओं के साथ शुरू करें और धीरे -धीरे पूर्ण डिजिटलाइजेशन को बढ़ावा दें। - सतत विकास

परिवर्तन के बाद, पेशेवर प्रतिभा और ज्ञान समर्थन की आवश्यकता होती है। उद्यमों को कर्मचारी प्रशिक्षण को मजबूत करना चाहिए, प्रतिभा का परिचय देना चाहिए और ज्ञान प्रबंधन प्रणालियों को स्थापित करना और बनाए रखना चाहिए।

"छोटे-फास्ट-लाइट-सटीक" हल्के डिजिटल परिवर्तन समाधान

विनिर्माण उद्यम ग्राहकों की सेवा में एक दशक से अधिक के अनुभव के साथ, APQ डिजिटल परिवर्तन के दौरान महत्वपूर्ण चुनौतियों का सामना करने वाली कंपनियों को गहराई से समझता है। इसलिए, APQ टीम डिजिटल कारखानों के परिचालन निष्पादन परत पर ध्यान केंद्रित करती है और "छोटे, तेज, हल्के, सटीक" के मुख्य दर्शन के आधार पर, विनिर्माण उद्यमों के लिए एक हल्के डिजिटल परिवर्तन समाधान का प्रस्ताव करती है। इस समाधान को 200 से अधिक शहरों और क्षेत्रों में कई प्रमुख ग्राहकों के लिए सफलतापूर्वक तैनात किया गया है, जो प्रतिदिन लाखों उपयोगकर्ताओं की सेवा कर रहा है, और उच्च ग्राहक मान्यता और दीर्घकालिक सहयोग प्राप्त किया है।

यह समाधान डिजिटल परिवर्तन में महत्वपूर्ण चुनौतियों को संबोधित करता है, जिसमें डेटा संग्रह, उपकरण स्थिरता, डेटा सुरक्षा, सुविधाजनक संचालन और रखरखाव, कर्मचारी प्रशिक्षण, और ज्ञान प्रतिधारण शामिल है, "औद्योगिक कंप्यूटर, IPC+ टूलचेन, डिजिटल वर्कस्टेशन, डॉ। क्यूआई डॉक्टर" की एक व्यापक पेशकश के माध्यम से, जिसमें हार्डवेयर समर्थन और सॉफ्टवेयर दोनों सेवाओं को शामिल किया गया है।

हल्के डिजिटल परिवर्तन समाधान

- औद्योगिक कंप्यूटर

एक मॉड्यूलर कोर अवधारणा के बाद, APQ उत्पादन लाइनों पर डेटा संग्रह, डेटा प्रोसेसिंग और उपकरण संचालन के लिए स्थिर और विश्वसनीय हार्डवेयर समर्थन प्रदान करने के लिए 4U औद्योगिक पीसी, एम्बेडेड औद्योगिक पीसी, और ऑल-इन-वन औद्योगिक पीसी सहित IPC उत्पादों की एक पूरी श्रृंखला प्रदान करता है।

- अनुशंसित मॉडल:

- उद्योग नियंत्रक: AK5097A2 (N97/8G/512G/2LAN/6USB 2.0/2com/18-28V)

- उद्योग नियंत्रक: AK6155A2-2LAN (I5-1155G7/8G/512G/2LAN/4USB 3.0/2USB 2.0/2COM/12-28V)

- औद्योगिक ऑल-इन-वन: PL156CQ-E5S (15.6 "कैपेसिटिव टचस्क्रीन/J6412/8g/128g/4com/2lan/6USB)

- औद्योगिक ऑल-इन-वन: PL156CQ-E6 (15.6 "कैपेसिटिव टचस्क्रीन/I3 8145U/8G/128G/4COM/2LAN/6USB)

- आईपीसी+ टूलचेन

आईपीसी+ टूलचेन औद्योगिक कंप्यूटरों पर केंद्रित एकीकृत निगरानी और प्रबंधन समाधान प्रदान करता है, जो आईपीसी की स्थिति में दृश्यता को सक्षम करता है, विसंगतियों की निगरानी, प्रारंभिक दोष चेतावनी और मुद्दों की ट्रेसबिलिटी, संचालन और रखरखाव को अधिक सुविधाजनक बनाता है। यह विभिन्न औद्योगिक परिदृश्यों पर लागू होता है, जैसे कि रोबोटिक्स, उत्पादन लाइनों और मानव रहित उपकरण, उपकरण धारणा और स्थिरता को बढ़ाने, अनियोजित डाउनटाइम को कम करना, और सिस्टम संचालन और रखरखाव लागत को कम करना।

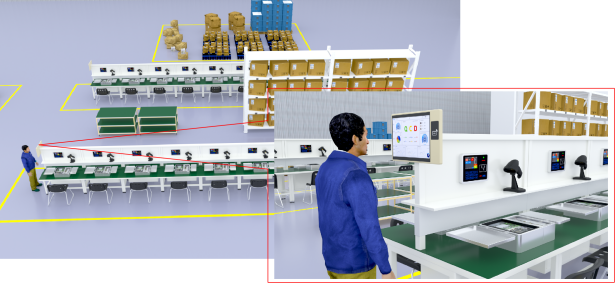

- अंकीय कार्यस्थल

उत्पादन निष्पादन, प्रक्रिया निष्पादन, गुणवत्ता निष्पादन, विसंगति का पता लगाने, ई-एसओपी, और एआई इंटरैक्शन जैसे प्रमुख अनुप्रयोगों के माध्यम से, डिजिटल वर्कस्टेशन टास्क डिस्पैचिंग, उत्पादन डेटा संग्रह और वास्तविक समय की निगरानी के लिए अनुमति देते हैं, समस्याओं को तुरंत हल करते हैं। डेटा डैशबोर्ड और रिपोर्ट के माध्यम से प्रदर्शित किया जाता है। सिस्टम हल्का है, सीखने में आसान है, और सहयोग की कठिनाइयों को कम करने, उत्पादन दक्षता बढ़ाने और उत्पादन प्रतिक्रिया की गति में सुधार करने के लिए सॉफ्टवेयर और हार्डवेयर दोनों को एकीकृत करता है।

- डॉ। क्यूई डॉक्टर

बड़े मॉडलों के आधार पर, डॉ। यह उद्यम के भीतर एक ज्ञान "फ्लाईव्हील" बनाता है, सभी को एक विशेषज्ञ में बदल देता है। यह तकनीकी और प्रतिभा प्रशिक्षण के साथ -साथ उद्यमों के लिए सुविधाजनक सेवाओं का समर्थन करता है।

वास्तविक दुनिया के आवेदन के मामले

- केस 1: ऑटोमोटिव मैन्युफैक्चरिंग

एक प्रसिद्ध घरेलू ऑटोमोटिव पार्ट्स प्रोसेसिंग कंपनी के लिए, APQ ने PL-E5/E6 सीरीज़ इंडस्ट्रियल ऑल-इन-वन पीसी का उपयोग करके MES लाइन सशक्तिकरण प्रदान किया। समाधान ने उपकरण दक्षता के बुद्धिमान प्रबंधन को सक्षम किया, उपकरण, उत्पादों और कर्मियों के लिए उत्पादन समय डेटा का विश्लेषण किया, ताकि उत्पादन लाइन पर समग्र उपकरण उपयोग की निगरानी की जा सके।

केस 2: इलेक्ट्रॉनिक्स विनिर्माण

एक प्रसिद्ध घरेलू इलेक्ट्रॉनिक्स निर्माता के लिए हजारों उपकरणों के साथ मुद्दों का सामना करना पड़ता है जिसमें वास्तविक समय की स्थिति संवेदन, अक्षम रखरखाव उपकरण, और रखरखाव डेटा के खराब प्रबंधन की कमी होती है, APQ ने E7-Q670 जैसे एम्बेडेड औद्योगिक पीसी को तैनात किया, जो कि दूरस्थ उपकरणों के लिए विश्वसनीय औद्योगिक-ग्रेड हार्डवेयर और IPC+ टूलचेन समाधान प्रदान करता है, जो कि रखरखाव दक्षता में सुधार करता है।

नए उत्पादन बलों की शुरूआत के साथ, विनिर्माण उद्यमों के त्वरित डिजिटल परिवर्तन एक अपरिहार्य प्रवृत्ति बन गया है। प्रासंगिक आंकड़ों के अनुसार, 2023 के अंत तक, चीन ने 421 राष्ट्रीय स्तर के प्रदर्शन कारखानों और 10,000 से अधिक प्रांतीय-स्तरीय डिजिटल कार्यशालाओं और बुद्धिमान कारखानों की खेती की थी। डिजिटल परिवर्तन पारंपरिक विनिर्माण उद्यमों के उन्नयन और प्रतिस्पर्धा के लिए महत्वपूर्ण मार्ग बन गया है। आगे बढ़ते हुए, APQ अधिक क्षेत्रों में एक महत्वपूर्ण भूमिका निभाता रहेगा, पारंपरिक विनिर्माण उद्योगों के परिवर्तन और उन्नयन को सशक्त बनाने और औद्योगिक खुफिया को बढ़ावा देने को बढ़ावा देने के लिए विश्वसनीय डिजिटल परिवर्तन समाधान प्रदान करेगा।

यदि आप हमारी कंपनी और उत्पादों में रुचि रखते हैं, तो हमारे विदेशी प्रतिनिधि, रॉबिन से संपर्क करने के लिए स्वतंत्र महसूस करें।

Email: yang.chen@apuqi.com

व्हाट्सएप: +86 18351628738

पोस्ट टाइम: दिसंबर -20-2024