Okwughere dị n'azụ

Dị ka asọmpi ahịa na-abawanye ụba, na-esiwanye ike ime ihe ike dị egwu na-apụta. N'afọ ndị na-adịbeghị anya, ọtụtụ nri na ụlọ ọrụ ọgwụgwụ amalitela iji usoro dị iche iche iji mebie ndị na-azụ ahịa, na-egosipụta uru ngwaahịa ha bara uru. Ọ bụ ezie na ndị na-azụ ahịa nwere ike ọ gaghị agbakọ ọnụ ọgụgụ nke swiiti na igbe ma ọ bụ ọgwụ na karama, maka azụmaahịa, maka ngụkọta nke nkeji ọzọ dị mkpa. Nke mbu, nke a na - emetuta onu ahia na uru. Nke abụọ, maka ụfọdụ n'ime ụlọ ọgwụ, ọnụ ọgụgụ nke nkeji na-ekpebi ọkọlọtọ usoro onunu ogwu, ebe njehie anaghị anabata. Ya mere, "na-agụta ọnụ bụ nzọụkwụ dị mkpa na usoro nkwakọ ngwaahịa nke ụlọ ọrụ nri na ụlọ ọrụ ọgwụ.

Ntụgharị site na ntuziaka maka ịgụta ọnụ

N'oge gara aga, ịgụta ihe oriri na ọgwụ na-adabere na ọrụ aka ọrụ. Ọ bụ ezie na usoro a na-akwụghị ụgwọ, usoro a nwere ihe ndọghachi azụ dị ukwuu, gụnyere ịmụ oge na-eri oge, kpụ ọkụ n'ọnụ, na njehie - na-arụ ọrụ. Ihe ndị na-eme ka ike na ndọpụ uche na ndọpụ uche na-edugakarị na ezighi ezi, na-emetụta ịdabere na ntụkwasị obi na izi ezi. N'afọ 1970, ụlọ ọrụ ndị na-eme ọgwụ na-agụta igwe elektrọnik, na-akara akara ngbanwe site na ntuziaka maka ịgụta ọnụ. Site na oganihu nke akpaaka na teknụzụ ọgụgụ isi, ahịa ụlọ maka ịgụta igwe na-anabata ihe eji eme ihe na sistemụ smart. Site na iji usoro ihe nlere na teknụzụ sensọ dị elu, ngwaọrụ ọnụọgụ nke ọgbara ọhụrụ na-enweta arụmọrụ akpaaka na nchịkwa nke arụmọrụ mgbe ị na-agbazi ego ọrụ na ike ọrụ.

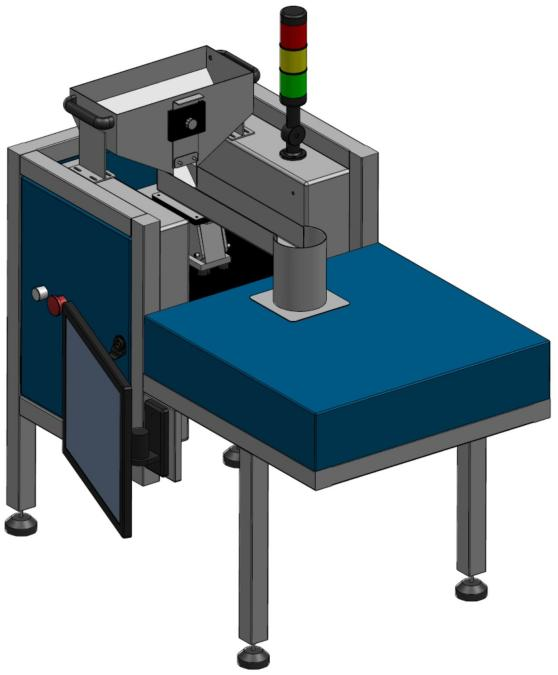

Mmegharị na igwe nlele sara mbara

Encriselọ ọrụ ụlọ na-eduga n'ụlọ na akụrụngwa akụrụngwa na-akpata ọgwụ na-ahụ anya na teknụzụ na teknụzụ na-enwetala ọtụtụ onye na-enwekarị ihe na-ahụ maka ngwaọrụ. Igwe nlele anya ya na-arụ ọrụ na-arụ ọrụ na teknụzụ nlele anya na usoro nkwenye siri ike iji dozie nsogbu ọdịnala. Dịka ọmụmaatụ, igwe ndị a na-ejikọ teknụzụ ihe atụ anya iji gbochie ngwaahịa ndị nwere nkwarụ ịbanye n'ahịa ahụ, na-eme ihe eji emepụta mmiri maka nrụpụta usoro nrụpụta, na -ebelata akara. Nkọwapụta ndị a kwalitere arụmọrụ arụmọrụ ma bulie asọmpi ngwaahịa.

Maka akụrụngwa dị elu dị otú ahụ, ụlọ ọrụ ahụ na-esetịpụrụ ihe dị omimi maka ihe ndị dị oke mkpa dịka mmepụta ihe niile na PCs niile. Ihe ndị a a chọrọ gụnyere nke ọma na mobilities atụmatụ, ikike nhazi onyonyo siri ike, ntụkwasị obi na nkwụsi ike na nhọrọ nrụpụta na nkwado dị mma.

Ngwọta APQ na nnyefe uru

Dịka onye na - eweta ihe na - eduga na nchịkọta nke ụlọ ọrụ, APQ guzobere mmekọrịta siri ike, yana ịrụ ọrụ ngwaahịa a kachasị elu site na arụmọrụ ngwaahịa a pụrụ ịdabere na ya, ọnụ ahịa dị oke ọnụ, na ọrụ ndị ọkachamara na - aza ya. Onye ahịa ahụ depụtara ihe ndị a chọrọ dabere na nsonaazụ ngwa a chọrọ nke na-agụta igwe ndị na-agụta igwe:

- Ndị na-eme ihe ngosi na-arụ ọrụ iji kwado nhazi nhazi na ọchụchọ.

- Usoro jụrụ oyi iji hụ na ọrụ kwụsiri ike ogologo oge.

- Ndakọrịta na igwefoto dị elu maka echiche doro anya.

- Insatelọ nnyefe mgbasa ozi dị elu dị elu, dị ka USB 3.0 ma ọ bụ karịa.

- Nchekwa nchekwa iji nabata nnukwu mpịakọta nke data onyonyo.

- Iji ngwa ọrụ dị mfe na akụrụngwa ndị ọzọ.

- Anti-Rebreation na Ntụgharị Ntinye uche iji merie gburugburu mmepụta ọrụ siri ike.

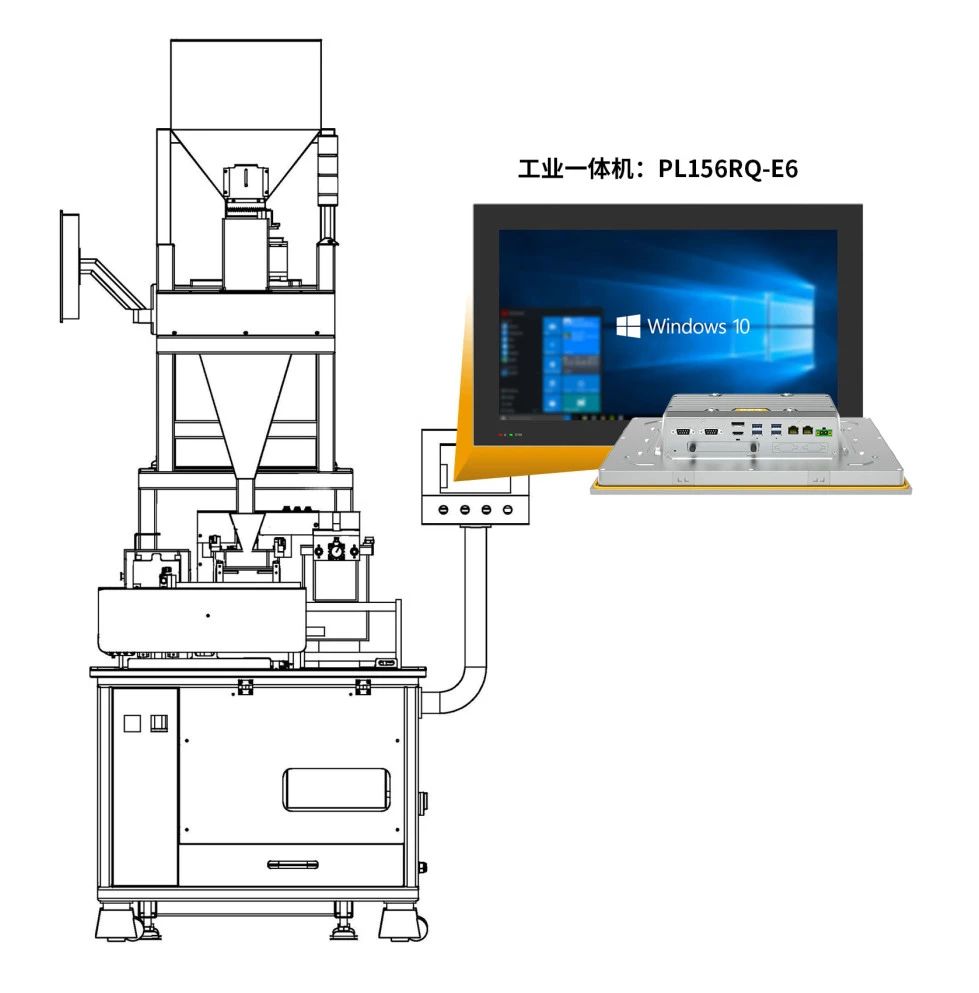

Onye njikwa ahịa mpaghara APQ zara ozugbo na mkpa onye ahịa ahụ ozugbo, duzie na nyocha miri emi, ma zụlite atụmatụ nhọrọ edoziri. A na-ahọpụta pl150RQ-e6 mmepụta PC niile dị ka ngalaba njikwa yana njikọta mmekọrịta maka ngwa ahụ.

Pl150RQ-e6, akụkụ nke usoro ọrụ ndị mepere emepe na Intel® nke 11 - Ult® - ị na-ebugharị arụmọrụ dị elu na ikike ike dị ala na gburugburu ebe obibi. Ọ na - eche Intel® gigabat Net Network Interfaces maka njikọ netwọkụ ngwa ngwa na nke kwụsiri ike ma na - akwado oghere ngosi abụọ nke ikuku na - emepụta. Nkwado draịvụ draịvụ na-akwado ya, na-enweghị atụ nke ihe ngosi, na-eme ka ọ bụrụ ihe ngosi dị elu, na-ebute ụkpụrụ IP65, ma na-eme ka ihe dị iche iche dị elu na-emepụta ihe.

Nhazi nke APQ nke APQ nke APQ, PL150RQ-e6 gafere ule nke teknụzụ ndị ahịa na obere oge, ịngmalite ngalaba njikwa igodo maka igwe nlele anya ha. Na mgbakwunye na mmekorita a, APQ enyela nhazi iche iche iji kwado akụrụngwa ndị ọzọ, dị ka igwe na-ahazi mara mma na mkpa na asọmpi nke ngwaahịa promietdị ha.

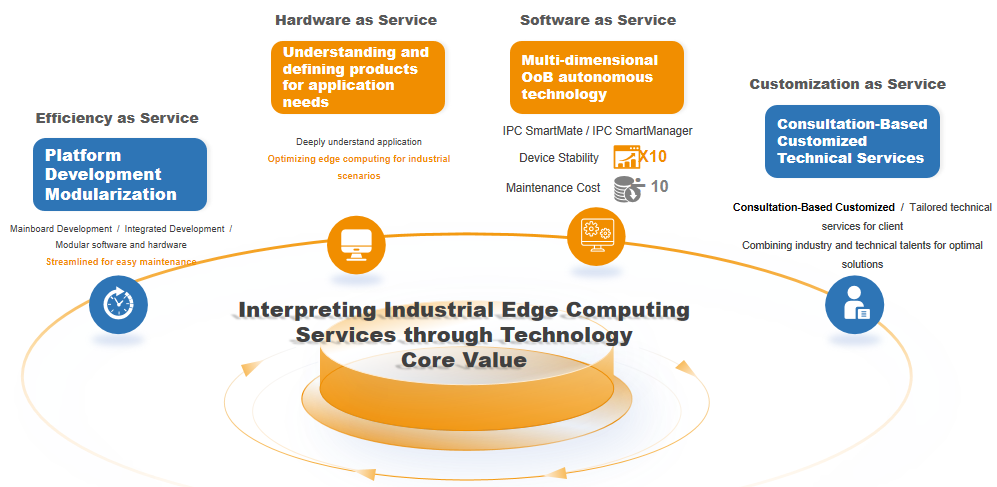

Nkàpụta nkà ihe ọmụma na "333"

Ikike APQ na-ezute ihe ndị ahịa chọrọ ngwa ngwa ị ga-enwe ezigbo nhazi site na akụrụngwa modular na-emepụta ihe nkà ihe ọmụma na ego nke nnwere onwe ya. Site na igwe nne na-agbatị onwe ya na kaadị mgbasa ozi 50 na-enye ohere na-enweghị mgbanwe iji mee ka ọrụ dị iche iche gaa n'osisi. Ọzọkwa, IPC + Ngwaọrụ na-eme ka ngwaike onwe gị, na-enyocha onwe gị, nhazi onwe onye, na ikike onwe gị, na-eme ka ị na-akwado ọgụgụ isi na ọrụ dị mma maka akụrụngwa nkwakọ ngwaahịa.

Ntinye aka na Nzaghachi ngwa ngwa ya "333", zuru oke ngwaahịa, yana ọrụ Nkwado-APQ enwetala nnabata dị elu site n'aka ndị ahịa.

Na-ele anya n'ihu: ụlọ ọrụ na-akwọ ụgbọala

Dị ka ihe na-emepụta ihe na-eme ka ihe na ndị na-azụ ahịa na-ebili, mkpa ọ dị mkpa iji ngwaahịa nkwakọbawanye, site na nha n'ahịa na-agbasa nwayọ. China apụtapụtawo dịka ahịa igwe na-ere ahịa ụwa. Na akụrụngwa nkwakọ ngwaahịa, mmepụta ihe PC na-abụghị naanị kwalite arụmọrụ arụpụta na usoro nkwakọ ọnụ, ma na-emekwa ka nyocha oge, ma nyekwa ntụkwasị obi na nkwụsi ike. Dị ka onye na-eweta ọrụ ọrụ na-eduga na-agbagha, APQ ka na-eme ka ngwaahịa ngwaahịa na ihe ọhụrụ, na-ebufe ya nke ọma na-agbakọ ngwaike na sọftụwia maka ụlọ ọrụ ụlọ ọrụ. Nkwado nkà ihe ọmụma "333", APQ chọrọ ịnya ọrụ ụlọ ọrụ smarter site na zuru oke, ọkachamara na nkwado ọsọ.

Ọ bụrụ na ị nwere mmasị na ụlọ ọrụ anyị na ngwaahịa anyị, nweere onwe gị ịkpọtụrụ onye nnọchi anya ya, Robin.

Email: yang.chen@apuqi.com

WhatsApp: +86 18351628738

Oge post: Dec-12-2024