Introductio Contextus

Machinae ad iniectionem fingendam instrumenta necessaria sunt in processu plasticae et latas applicationes habent in industriis sicut autocinetica, electronica, involucris, constructione, et curatione valetudinis. Cum progressibus technologicis, mercatus postulat qualitatis moderationem strictiorem, administrationem in situ auctam, et sumptuum moderationem emendatam. Introductio MES (Systema Executionis Fabricationis) facta est mensura clavis pro societatibus iniectionis fingendae ad transformationem digitalem et progressionem sustinendam assequendam.

Inter haec, computatra personalia industrialia APQ omnia-in-uno partes cruciales agunt in applicationibus MES intra industriam injectionis formandae, propter excellentem perfunctionem, stabilitatem, et adaptabilitatem ad varia ambitus.

Commoda MES in Industria Injectionis Formandae

Introductio systematum MES in industriam injectionis formae efficientiam productionis efficaciter augere, administrationem opum optimizare, qualitatem productorum emendare, administrationem exquisitam permittere, et ad mutantes mercatus postulata accommodare potest.

- Efficacia ProductionisSystema MES statum productionis in tempore reali observant, ordinationem temporis sponte accommodant, moras minuunt, et efficientiam augent.

- Sustentatio InstrumentorumCum ad machinas iniectionis formandae adhibentur, systemata MES statum apparatuum tempore reali observant, vitam machinae extendunt, notitias sustentationis notant, et sustentationem praeventivam dirigunt.

- Administratio OpumSystema MES usum materiarum et inventarium observant, sumptus repositionis minuunt, et requisita materiarum automatice computant.

- Cura QualitatisSystema processus productionis tempore reali monitorat ut qualitas producti confirmetur, notitias ad problemata qualitatis investigandas registrat.

Proprietates Claves Computatrorum Omnino-in-Uno Industrialium APQ

Systema MES sunt systemata informationis critica in fabricatione quae processus productionis observant, administrant, et optimizant. Computatra personalia industrialia APQ specialiter ad ambitus industriales designata sunt, offerentes firmitatem, efficaciam magnam, interfacies multiplices, et facultatem requisitis environmentalibus severis occurrendi. Stabiliter in condicionibus asperis operari possunt cum proprietatibus ut constructione robusta et resistentia pulveris et aquae.

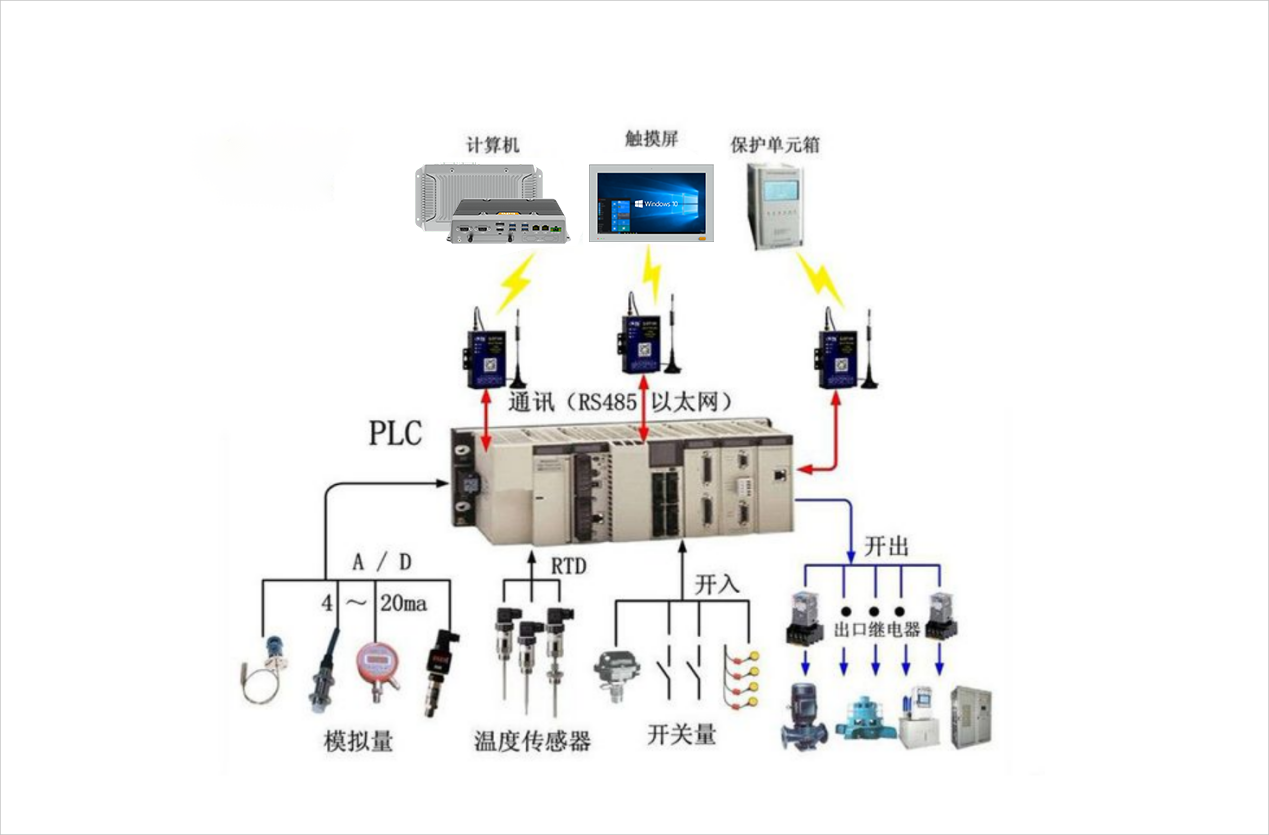

Hae proprietates computatra APQ omnia-in-uno late in systematibus terrestribus apparatuum potentiae adhiberi faciunt. Ut terminales acquisitionis datorum, data systematis terrestribus, ut resistentiam et currentem, in tempore reali monitorare possunt. Programmate IPC SmartMate et IPC SmartManager proprietario APQ instructi, moderationem et administrationem remotam, configurationem parametrorum pro stabilitate systematis, monita et locum errorum, inscriptionem datorum, et generationem relationum ad sustentationem et optimizationem systematis sustinendam permittunt.

Commoda Computatrorum Omnino-in-Uno Industrialium APQ

- Monitorium et Acquisitio Datorum in Tempore Reali

Computatra personalia (PC) APQ, quasi instrumentum principale in systemate MES ad iniectionem formandam, notitias in tempore reali de statu operationis instrumentorum colligunt, inter quas parametri critici ut tensio, fluxus electricus, temperatura et humiditas. Sensoria et interfacies incorporatae transmissionem notitiarum celerem ad centrum monitorium permittunt, operariis accuratam informationem in tempore reali praebentes. - Analysis et Monita Intelligentia

Potentibus facultatibus ad notitias tractandas, computatra industrialia APQ omnia-in-uno notitias in tempore reali examinant ut pericula securitatis et errores potentiales cognoscant. Utentibus regulis et algorithmis praefinitis admonitionis, systema signa admonitionis automatice mittere potest ut operarios certiores faciat ut actionem tempestive suscipiant et accidentia prohibeant. - Imperium Remotum et Operationes

Computatra industrialia APQ omnia-in-uno functiones moderationis et operationis remotae sustinent, permittens operariis per rete se inscribere ad apparatum in lineis productionis remote moderandum et operandum. Haec functio remota efficientiam insigniter auget et sumptus sustentationis minuit. - Integratio et Coordinatio Systematis

Computatra personalia industrialia APQ omnia-in-uno praeclaram compatibilitatem et amplificationem offerunt, integrationem et coordinationem cum aliis subsystematibus et apparatibus sine intermissione permittentes. Interfaciebus et protocollis unitis, computatra communicationem datorum et collaborationem inter varia subsystemata faciliorem reddunt, intelligentiam totius systematis MES augentes. - Securitas et Fiducia

Computatra industrialia omnia-in-uno APQ plus quam 70% microplacis domestice productis utuntur et independenter evoluta et designata sunt, summam securitatem praebentes. Praeterea, magnam firmitatem et stabilitatem exhibent, praeclaram efficaciam sub operatione diuturna et condicionibus asperis servantes.

Applicationes in Industria Injectionis Formandae

Computatra computatralia industrialia omnia-in-uno APQ plura munera in systematibus MES industriae injectionis formae funguntur, inter quae:

- Acquisitio et processus datorum

- Imperium automationis et ductio operativa

- Publicatio informationum et inspectio qualitatis

- Monitorium et administratio remota

- Adaptabilitas ad condiciones difficiles

- Visualizatio et analysis datorum

Hae functiones simul efficientiam productionis, qualitatem producti, et administrationem informationum in industria injectionis formandae augent. Prospiciendo, dum fabricatio ad intelligentiam digitalem transit, computatra personalia industrialia APQ omnia-in-uno partes magis ac magis vitales in variis campis agent, progressus altiores in intelligentia industriali impellentes.

Recentissima exempla commendata pro MES

| Modellum | Configuratio |

|---|

| PL156CQ-E5S | 15.6 unciae / 1920*1080 / Tegumentum Tactile Capacitivum / J6412 / 8GB / 128GB / 4COM / 2LAN / 6USB |

| PL156CQ-E6 | 15.6 unciae / 1920*1080 / Tegumentum Tactile Capacitivum / I3 8145U / 8GB / 128GB / 4COM / 2LAN / 6USB |

| PL215CQ-E5S | 21.5 unciae / 1920*1080 / Tegumentum Tactile Capacitivum / J6412 / 8GB / 128GB / 4COM / 2LAN / 6USB |

| PL215CQ-E6 | 21.5 unciae / 1920*1080 / Tegumentum Tactile Capacitivum / I3 8145U / 8GB / 128GB / 4COM / 2LAN / 6USB |

Si societate nostra et productis tuis interest, libenter cum legato nostro transmarino, Robin, communicare potes.

Email: yang.chen@apuqi.com

WhatsApp: +86 18351628738

Tempus publicationis: XXII Novembris MMXXIV