Background Introduction

Wafer dicing machines are a critical technology in semiconductor manufacturing, directly impacting chip yield and performance. These machines precisely cut and separate multiple chips on a wafer using lasers, ensuring the integrity and performance of each chip in subsequent packaging and testing stages. As the industry rapidly advances, there are increasing demands for higher precision, efficiency, and environmental sustainability in dicing machines.

Key Requirements for Wafer Dicing Machines

Manufacturers currently focus on several key indicators for wafer dicing machines:

Cutting Precision: Nanometer-level accuracy, which directly impacts chip yield and performance.

Cutting Speed: High efficiency to meet mass production demands.

Cutting Damage: Minimized to ensure chip quality during the cutting process.

Automation Level: High degree of automation to reduce manual intervention.

Reliability: Long-term stable operation to reduce failure rates.

Cost: Lower maintenance costs to improve production efficiency.

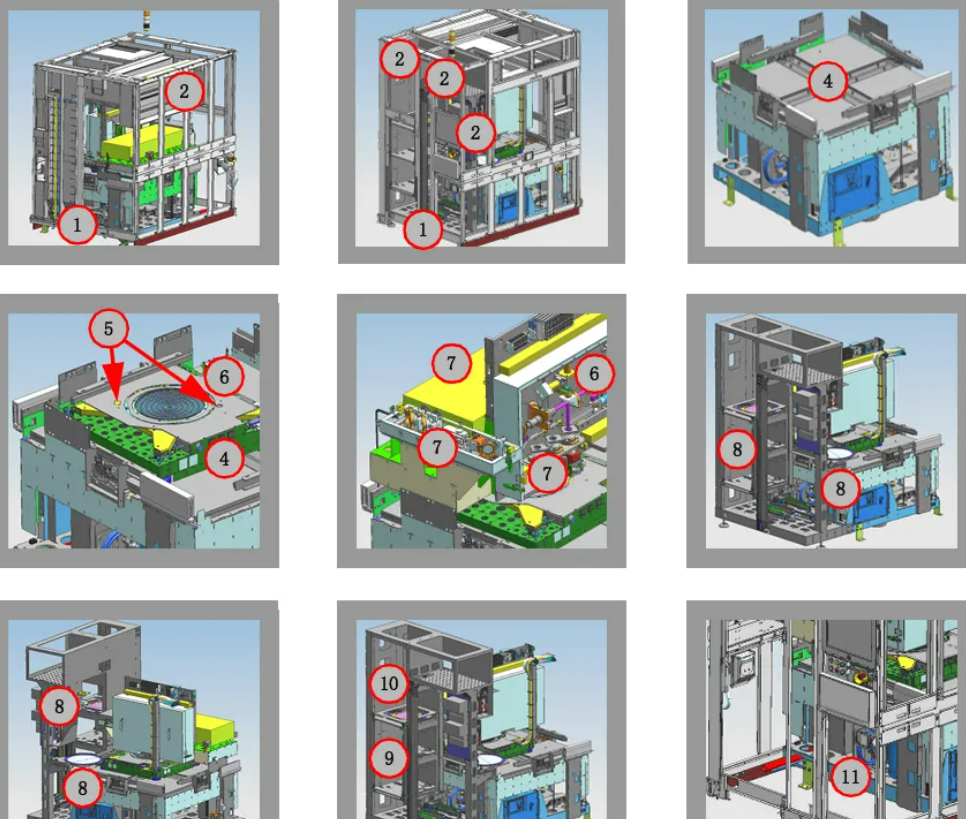

Wafer dicing machines, as precision equipment, comprise more than ten subsystems, including:

- Power Distribution Cabinet

- Laser Cabinet

- Motion System

- Measurement System

- Vision System

- Laser Beam Delivery System

- Wafer Loader and Unloader

- Coater and Cleaner

- Drying Unit

- Fluid Supply Unit

The control system is crucial as it manages the entire process, including setting cutting paths, adjusting laser power, and monitoring the cutting process. Modern control systems also require functionalities like auto-focusing, auto-calibration, and real-time monitoring.

Industrial PCs as the Core Control Unit

Industrial PCs (IPCs) are often used as the core control unit in wafer dicing machines, and they must meet the following requirements:

- High-Performance Computing: To handle high-speed cutting and data processing needs.

- Stable Operating Environment: Reliable performance in harsh conditions (high temperature, humidity).

- High Reliability and Safety: Strong anti-interference capabilities to ensure cutting accuracy and safety.

- Extensibility and Compatibility: Support for multiple interfaces and modules for easy upgrades.

- Adaptability: Flexibility to meet different wafer dicing machine models and production requirements.

- Ease of Operation and Maintenance: User-friendly interface and easy maintenance to reduce costs.

- Efficient Cooling System: Effective heat dissipation to ensure stable operation.

- Compatibility: Support for mainstream operating systems and industrial software for easy integration.

- Cost-Effectiveness: Reasonable pricing while meeting the above requirements to fit budget constraints.

APQ Classic 4U IPC:

IPC400 Series

The APQ IPC400 is a classic 4U rack-mounted chassis that conforms to industry standards. It is designed for both wall-mounted and rack-mounted systems and offers a cost-effective industrial-grade solution with full options for backplanes, power supplies, and storage devices. It supports mainstream ATX specifications, featuring standard dimensions, high reliability, and a rich selection of I/O interfaces (including multiple serial ports, USB ports, and display outputs). It can accommodate up to 7 expansion slots.

Key Features of the IPC400 Series:

- Fully molded 19-inch 4U rack-mount chassis.

- Supports Intel® 2nd to 13th generation desktop CPUs.

- Compatible with standard ATX motherboards and 4U power supplies.

- Supports up to 7 full-height expansion slots to meet diverse industry needs.

- User-friendly design with tool-free maintenance for front system fans.

- Tool-free PCIe expansion card bracket with high shock resistance.

- Up to 8 anti-vibration and shock-resistant 3.5-inch hard drive bays.

- Optional 2 x 5.25-inch drive bays.

- Front panel with USB ports, power switch, and indicators for easy system maintenance.

- Anti-tamper alarm and lockable front door to prevent unauthorized access.

Latest Recommended Models for Wafer Dicing Machines

| Type | Model | Configuration |

|---|---|---|

| 4U Rack-Mount IPC | IPC400-Q170 | IPC400 chassis / Q170 chipset / 2 LAN / 6 USB 3.2 Gen1 + 2 USB 2.0 / HDMI + DP / i5-6500 / DDR4 8GB / M.2 SATA 512GB / 2 x RS232 / 300W ATX PSU |

| 4U Rack-Mount IPC | IPC400-Q170 | IPC400 chassis / Q170 chipset / 2 LAN / 6 USB 3.2 Gen1 + 2 USB 2.0 / HDMI + DP / i7-6700 / 2 x DDR4 8GB / M.2 SATA 512GB / 2 x RS232 / 300W ATX PSU |

| 4U Rack-Mount IPC | IPC400-H81 | IPC400 chassis / H81 chipset / 2 LAN / 2 USB 3.2 Gen1 + 4 USB 2.0 / HDMI + DVI-D / i5-4460 / DDR3 8GB / M.2 SATA 512GB / 2 x RS232 / 300W ATX PSU |

| 4U Rack-Mount IPC | IPC400-H81 | IPC400 chassis / H81 chipset / 2 LAN / 2 USB 3.2 Gen1 + 4 USB 2.0 / HDMI + DVI-D / i7-4770 / DDR3 8GB / M.2 SATA 512GB / 2 x RS232 / 300W ATX PSU |

If you're interested in our company and products, feel free to contact our overseas representative, Robin.

Email: yang.chen@apuqi.com

WhatsApp: +86 18351628738

Post time: Nov-08-2024