In the past, traditional fabric quality inspections in the textile industry were primarily carried out manually, which led to high labor intensity, low efficiency, and inconsistent accuracy. Even highly experienced workers, after more than 20 minutes of continuous work, experience a decline in their ability to identify fabric defects.

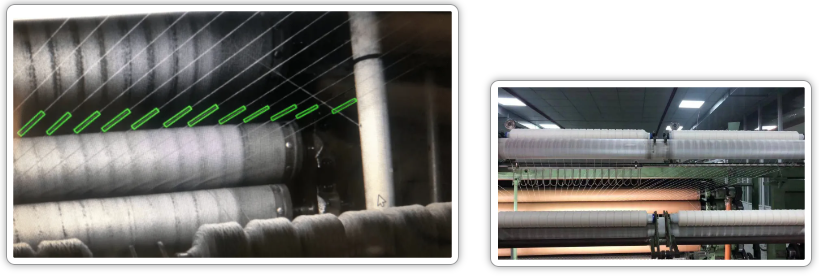

To address this issue, visual solution providers have utilized the advancing AI visual algorithm technology to develop smart fabric inspection machines to replace skilled workers. These machines can inspect fabrics at speeds of 45-60 meters per minute, improving efficiency by 50% compared to manual inspections.

These machines are capable of detecting over 10 types of defects, including holes, stains, yarn knots, and more, with a fabric defect detection rate of up to 90%. The use of smart fabric inspection machines significantly reduces operational costs for companies.

Most smart fabric inspection machines on the market use traditional setups, including industrial PCs, graphics cards, and capture cards. However, in textile mills, the humid air caused by wetting fabric with water and the presence of floating lint can easily cause corrosion and short circuits in traditional industrial PCs and graphics cards, resulting in economic losses and high after-sales costs.

The APQ TAC-3000 replaces the need for capture cards, industrial PCs, and graphics cards, offering improved stability while reducing procurement and after-sales costs.

Part 1: Features and Advantages of APQ TAC-3000

The TAC-3000, designed for edge computing, utilizes the NVIDIA Jetson series module as its core and has the following features:

- Powerful AI Computing Capability: With up to 100 TOPS of computing power, it meets the high computational demands of complex visual inspection tasks.

- Flexible Expandability: Supports a variety of I/O interfaces (Gigabit Ethernet, USB 3.0, DIO, RS232/RS485) for easy connection to external devices and sensors.

- Wireless Communication: Supports 5G/4G/WiFi expansion for stable communication in various environments.

- Wide Voltage Input & Compact Design: Supports DC 12-28V input and features a fanless, ultra-compact design suitable for installation in tight spaces.

- Deep Learning Applications: Compatible with TensorFlow, PyTorch, and other deep learning frameworks, enabling the deployment and training of models for improved inspection accuracy.

- Low Power Consumption & High Efficiency: The fanless design, combined with the Jetson platform, ensures low power consumption and stable performance in environments with humidity and high heat, reducing operational costs and energy consumption.

TAC-3000 Specifications

Supports NVIDIA® Jetson™ SO-DIMM core board

High-performance AI controller with up to 100 TOPS of computing power

Three Gigabit Ethernet ports, four USB 3.0 ports

Optional 16-bit DIO, 2 RS232/RS485 configurable COM ports

Supports 5G/4G/WiFi expansion

DC 12-28V wide voltage input

Fanless, ultra-compact design with a high-strength metal body

Suitable for desktop or DIN installation

Smart Fabric Inspection Case

The APQ TAC-3000 controller, based on the NVIDIA Jetson platform, offers excellent computing power, stability, and cost-effectiveness. It has broad applications in AI visual inspection fields, such as fabric inspection, yarn break detection, electrode coating defect detection, and more. APQ continues to provide reliable integrated industrial intelligent computing solutions to help advance the "Made in China 2025" initiative.

Post time: Aug-30-2024