Screws, nuts, and fasteners are common components that, though often overlooked, are essential in nearly every industry. They are widely used across various sectors, making their quality critically important.

While every industry strictly controls the production quality of fasteners, ensuring that not a single screw is defective, manual inspection methods can no longer keep up with the current demands for mass production of screws. As modern intelligent technology advances, optical screw sorting machines have gradually taken on the critical role of quality control.

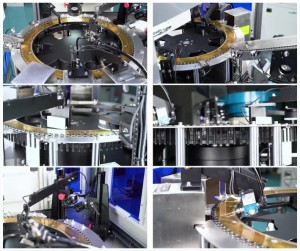

The optical screw sorting machine is a new type of automated equipment designed to inspect and sort screws and nuts. It primarily replaces manual inspection for various types of screws and nuts, including size detection, appearance inspection, and defect detection. The machine automatically completes feeding, inspection, quality judgment, and sorting tasks, significantly improving the accuracy and speed of screw and nut appearance inspection while reducing manual inspection costs. It is an ideal device for screw and nut appearance inspection, capable of inspecting different types of screws and nuts across a wide range of inspection items.

Look, Measure, Sort, Pick, Place - these are the key steps in the inspection process. The optical screw sorting machine replaces manual inspection and sorting work by simulating these human actions. The quality of these actions depends on its "brain." The industrial PC, as an essential part of the optical screw sorting machine, serves as its "brain," making the machine's requirements for the industrial PC extremely stringent.

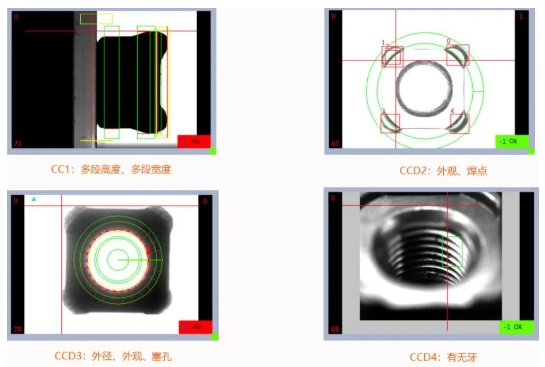

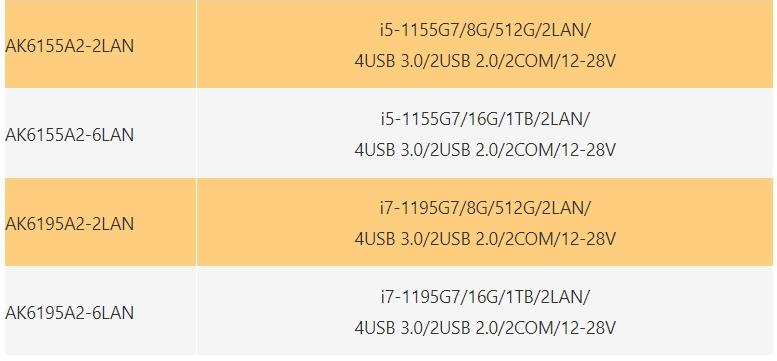

Firstly, from the application scenario and requirements of the optical screw sorting machine, it is clear that the sorting machine needs to capture images of screws from multiple angles, requiring 3-6 cameras to automatically detect and classify screw dimensions, shapes, and surface quality, ensuring rapid rejection of defective products. Due to the low cost of screws, the optical screw sorting machine also demands high cost-effectiveness from the industrial PC.

APQ's AK6 industrial PC demonstrates significant application advantages in screw sorting machines with its high performance, flexible expandability, and industrial-grade design. By integrating machine vision systems and real-time detection algorithms, it achieves efficient and high-precision sorting and classification of screws, enhancing production efficiency and product quality. Additionally, its real-time monitoring and feedback functions, along with data recording and analysis capabilities, provide strong support for production management and quality control.

Post time: Aug-15-2024