Hyrje në Sfond

Makineritë CNC: Pajisjet Thelbësore të Prodhimit të Avancuar

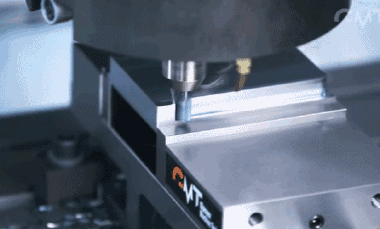

Makineritë CNC, të cilat shpesh quhen "makina industriale nënë", janë thelbësore për prodhimin e përparuar. Të përdorura gjerësisht në industri të tilla si automobilistika, hapësira ajrore, makineritë inxhinierike dhe teknologjia elektronike e informacionit, makinat CNC janë bërë një komponent kyç i prodhimit inteligjent në epokën e Industrisë 4.0.

Makineritë CNC, shkurt për makinat me kontroll numerik kompjuterik, janë makina të automatizuara të pajisura me sisteme kontrolli programor. Ato integrojnë sisteme kontrolli dixhital në makinat tradicionale për të arritur përpunim me precizion të lartë dhe efikasitet të lartë të lëndëve të para, siç janë pjesët metalike, në pjesë makinerie me forma, dimensione dhe përfundime sipërfaqësore specifike. Këto mjete optimizojnë rrjedhat e punës dhe ulin kostot e prodhimit. PC-të industriale të integruara të APQ, me integrimin e tyre të lartë, përshtatshmërinë e fortë dhe stabilitetin, luajnë një rol jetësor në këtë fushë, duke rritur ndjeshëm efikasitetin dhe cilësinë për shumë ndërmarrje prodhuese.

Roli i PC-ve industriale të integruara në mjetet e makinës CNC

Si "truri" i makinerive CNC, njësia e kontrollit duhet të trajtojë programe të ndryshme kompjuterike për kontrollin e makinerive, kode kontrolli të procesit dhe të ekzekutojë detyra të tilla si gdhendja, përfundimi, shpimi dhe prerja, zgavrimi, profilimi, serializimi dhe frezimi i filetove. Gjithashtu, ajo duhet t'i rezistojë mjediseve të ashpra të punës me pluhur, dridhje dhe ndërhyrje, duke siguruar njëkohësisht shpërndarje të shkëlqyer të nxehtësisë dhe stabilitet 24/7. Këto aftësi sigurojnë funksionim optimal dhe inteligjent të makinerive.

Makineritë tradicionale CNC shpesh mbështeten në njësi të shumta kontrolli dhe pajisje kompjuterike të ndara. PC-të industriale të integruara të APQ-së thjeshtojnë strukturën e sistemit duke integruar komponentë kyç si kompjuterët dhe kontrolluesit në një shasi kompakte. Kur lidhen me një panel industrial me ekran me prekje, operatorët mund të monitorojnë dhe menaxhojnë makinat CNC nëpërmjet një ndërfaqeje të vetme të integruar me prekje.

Studimi i Rastit: Zbatimi në një Kompani Kryesore të Automatizimit Industrial

Një klient, një ndërmarrje kryesore në kontrollin e automatizimit industrial, përqendrohet në prodhimin e pajisjeve të nivelit të mesëm dhe të lartë. Bizneset e tyre kryesore përfshijnë produkte të automatizimit industrial, pajisje automatizimi dhe pajisje mekatronike. Makineritë CNC, si një nga bizneset e tyre kryesore, zënë një pjesë të konsiderueshme të tregut çdo vit.

Sfidat në menaxhimin tradicional të punishteve CNC që kërkojnë zgjidhje urgjente përfshijnë:

- Thyerja e Siloseve të InformacionitTë dhënat e shpërndara të prodhimit nëpër faza të ndryshme nuk kanë integrim në një platformë të unifikuar, duke e bërë të vështirë monitorimin e punishteve në kohë reale.

- Përmirësimi i Efikasitetit të MenaxhimitRegjistrimi dhe statistikat manuale janë joefikase, të prirura ndaj gabimeve dhe nuk arrijnë të përmbushin kërkesat e reagimit të shpejtë të prodhimit modern.

- Ofrimi i Mbështetjes Shkencore për VendimeMungesa e të dhënave të sakta të prodhimit në kohë reale pengon vendimmarrjen shkencore dhe menaxhimin e saktë.

- Përmirësimi i Menaxhimit në VendTransmetimi i vonuar i informacionit pengon menaxhimin efektiv në vend dhe zgjidhjen e problemeve.

APQ ofroi PC-në industriale të integruar E7S-Q670 si njësi kryesore kontrolli, të lidhur me një panel klienti të personalizuar. Kur u çiftëzua me softuerët e patentuar IPC Smartmate dhe IPC SmartManager të APQ-së, sistemi arriti kontroll dhe menaxhim në distancë, konfigurime parametrash për stabilitet, paralajmërime për defekte dhe regjistrim të të dhënave. Ai gjithashtu gjeneroi raporte operimi për të mbështetur mirëmbajtjen dhe optimizimin e sistemit, duke ofruar vendimmarrje shkencore dhe efektive për menaxhimin në vend.

Karakteristikat kryesore të APQ Embedded Industrial PC E7S-Q670

Platforma E7S-Q670, e projektuar për automatizimin industrial dhe aplikacionet e informatikës në skaje, mbështet procesorët më të fundit të Intel, duke përfshirë seritë Core të gjeneratës së 12-të dhe të 13-të, Pentium dhe Celeron. Specifikimet kryesore përfshijnë:

- Procesorë me Performancë të LartëMbështet CPU-të Intel® Core / Pentium / Celeron për desktop (TDP 65W, paketa LGA1700), duke ofruar performancë dhe efikasitet të jashtëzakonshëm energjetik.

- Çipseti Intel® Q670Ofron një platformë të qëndrueshme hardueri dhe aftësi të gjera zgjerimi.

- Ndërfaqet e RrjetitPërfshin 2 porta rrjeti Intel (11GbE dhe 12.5GbE) për lidhje rrjeti me shpejtësi të lartë dhe të qëndrueshme për të përmbushur kërkesat e transmetimit të të dhënave dhe komunikimit në kohë reale.

- Daljet e ShfaqjesOfron 3 dalje ekrani (HDMI, DP++ dhe LVDS të brendshme) që mbështesin rezolucion deri në 4K@60Hz për nevojat e ekranit me definicion të lartë.

- Opsionet e ZgjerimitOfron ndërfaqe të pasura USB, seriale, PCIe, mini PCIe dhe slote zgjerimi M.2 për konfigurime të personalizuara në skenarë kompleksë të automatizimit industrial.

- Dizajn Ftohjeje EfikasFtohja aktive inteligjente e bazuar në ventilator siguron stabilitetin e sistemit nën ngarkesa të larta.

Përfitimet e E7S-Q670 për Makineritë CNC

- Monitorim dhe Mbledhje të të Dhënave në Kohë Reale

E7S-Q670 mbledh të dhëna kryesore operative si tensioni, rryma, temperatura dhe lagështia, duke i transmetuar ato në qendrën e monitorimit për monitorim të saktë në kohë reale. - Analiza dhe Alarmet Inteligjente

Përpunimi i avancuar i të dhënave identifikon rreziqet dhe defektet e mundshme të sigurisë. Algoritmet e paracaktuara shkaktojnë alarme, duke mundësuar marrjen e masave parandaluese në kohë. - Kontroll dhe funksionim në distancë

Operatorët mund të kontrollojnë dhe menaxhojnë pajisjet nga distanca nëpërmjet hyrjes në rrjet, duke përmirësuar efikasitetin dhe duke ulur kostot e mirëmbajtjes. - Integrimi dhe Koordinimi i Sistemit

Sistemi centralizon menaxhimin për pajisje të shumta, duke optimizuar burimet dhe oraret e prodhimit. - Siguria dhe Besueshmëria

Dizajni i patentuar siguron siguri, besueshmëri dhe performancë të qëndrueshme në kushte të vështira dhe operacione të zgjatura.

PC-të industriale të integruara janë thelbësore për prodhimin inteligjent, duke nxitur transformimin dixhital në makinat CNC. Zbatimi i tyre përmirëson efikasitetin, automatizimin dhe kontrollin e cilësisë në prodhim. APQ është gati të luajë një rol kyç në avancimin e inteligjencës industriale në më shumë sektorë, ndërsa dixhitalizimi i prodhimit thellohet.

Nëse jeni të interesuar për kompaninë dhe produktet tona, mos ngurroni të kontaktoni përfaqësuesin tonë jashtë vendit, Robin.

Email: yang.chen@apuqi.com

WhatsApp: +86 18351628738

Koha e postimit: 29 nëntor 2024